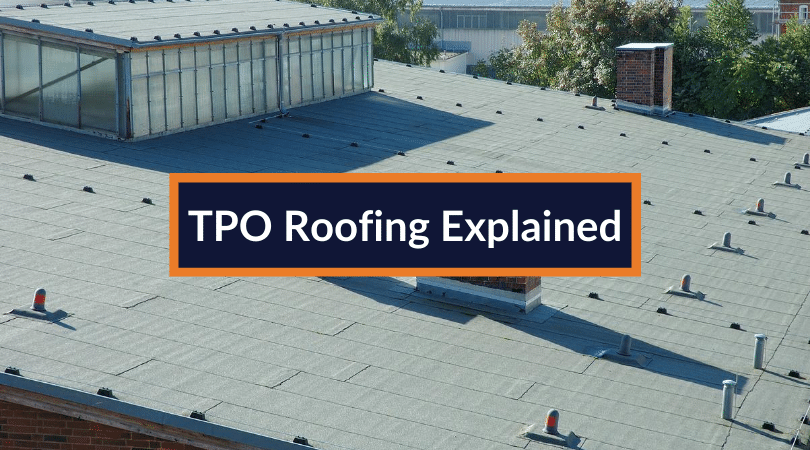

There are many options out there for flat or low slant roofing including TPO (thermoplastic olefin). TPO is a cost effective roofing system that is good for longevity and is energy efficient.

What is TPO?

TPO is a roofing membrane made of ethylene propylene rubber. It is made by combining rubber ethylene, and propylene through a chemical reaction. This creates a nice surface for roofs, but itself is not very strong. Before the TPO is set up, substances are added for durability; such as fiberglass, carbon filler, and talc.

TPO Membrane is a great option to replace a rubber roof. TPO is cost effective, energy-saving, and is more durable than your standard rubber roof. Since its creation, TPO Membranes have led the US in single-ply roofing systems due to its durability and ability for hot welding seams, repairs, and overall toughness to the elements.

Different TPO Options

TPO Roofing for flat or semi-flat roofing comes with different options in colors, thickness, width, and more. Considering these options before buying is crucial to the longevity and the efficiency level of the roof. Colors include white, light gray, and black. White is the most energy and cost effective due to the ability to reflect the sun.

Residential options include rolls of membrane from 45mil (0.45”) thickness to 60mil (0.60”). Depending on the manufacturer the rolls come in 6 feet width with a length of 100 feet. This allows for long passes and less seams in the roof. Seams will be the weak spots as they are only hot welded together.

Commercial options are generally built a little different. Each manufacturer has their own specs, but for a commercial building you will likely see a thickness of 80mil (0.80”). Every commercial roof is different, but the rolls can come up to 12 feet wide x 100 feet long. Smaller rolls are available for edges, overhangs, and other miscellaneous areas.

TPO is a great option for a cost effective, solid roofing system, but please consider the pros and cons of TPO before purchasing.

At What Cost?

There are many factors to consider when working up a price on a TPO roof. For example, a flat roof in an expensive metro area with limited access may be significantly more expensive to install. Whereas, an easy to install roof in an open area will reduce cost of man hours. Material availability is one more option to consider before purchasing a roof. It is best to consult with a professional roofing company before making any decisions.

Residential TPO roofing will cost anywhere between $6.50 and $11.50 per square foot installed. An average-size 1,200 sq/ft flat roof will cost between $7,800 and $13,800 depending on the factors pointed out above. Variables such as different roof layouts, home location, what the contractor uses for TPO, what they charge, etc.

Other factors of price include slope of the roof, whether the home is one or two-story, material cost as well as supplies, disposal of the roof torn off, permits, contractor installation, and finally a 5 year workmanship warranty provided.

Pros of TPO Roofing

TPO Roofing is widely used in the flat-roof industry. A TPO Membrane takes the advantages of its competitors in one membrane. TPO takes the best qualities of EPDM and PVC roofing and combines them for a flexible, energy and cost efficient option. Highly recommended for both residential and commercial flat roofing due to these simple but effective qualities.

Flexibility is a huge factor when installing a TPO roof. Flexibility allows the material to conform to whatever surface the material is being placed on. Great for rip resistance, movement, punctures, and falling objects as well as the changing seasons and temperatures.

When a TPO roof is exposed to the sun, it reflects the sun and holds up against the harmful UV Rays. The material expands and contracts with changing temperatures without tearing and cracking. The seams are 3-4 times stronger than the standard EPDM seams and withstand the constant movement.

Finally, a TPO roof is an Energy-Star rated roof as the white or light grey colors are great at reflecting the sun and heat. This can reduce heating and cooling bills for your home or business. Creating a better atmosphere inside during the hot summer months.

Cons of TPO Roofing

There are many pros to a TPO roof, but there are also some important cons to consider before purchasing one. TPO Roofing is still a fairly new process which means that the material over the years has changed. Not having experienced the longevity of the material in the elements has caused issues to arise. Manufacturers are updating their process, materials, and more to create a better product. Basically, some TPO’s are better than others.

ASTM Standards have been created for TPO roofing materials but are continually being edited for a better product and standard.

Throughout the lifecycle of TPO roofing, the material has been modified. So looking through the past you may see recalled roofing, cracked material, seems coming apart, leaks, and other failures. These failures are due to a number of factors such as a faulty install, exposure to excessive heat or cold, a bad chemical process, and other factors.

Although there are some cons to this roofing material, there is always an upside. Manufacturers are using the ASTM Standards to create a better line of products for future roofs. Look at it this way. The record shows that the TPO membrane has been tested for the past 30 years and approved along the way. So, if you were to go with a TPO roof, you would be getting a constantly improved product. Just keep your options open and research on your own and with your roofing expert.

Material Quality

It is important to get the best quality material for your application and the best installer to ensure the material is going to be set for its lifetime.

The quality of the membrane is important as it has been in service for such a short time compared to other roofing systems. Consider finding a manufacturer that has been around for the duration of the product. This means the manufacturer themselves can tell you what upgrades have happened over the years, and can give you examples of failures and how they fixed them. This will give you a reputable source for the highest quality material. You may run across offers from a new company for a cheaper material, but it may not be the best quality. This will be up to you to compare the make-up of the material. Get spec sheets and compare for your safety.

Energy-Efficiency

Energy-Efficiency is an important factor in choosing the right material. There is a 3 year Energy-Star rating that is applied to certain TPO’s. Be sure that the manufacturer has the correct paperwork and specs for the Energy-Star ratings.

Textured vs Smooth TPO Membrane. Smooth TPO is used most frequently to reflect the sun for the Energy-Star Rating. A textured TPO can collect algae, dirt, ice, and cause damage more frequently than a smooth TPO.

Final Tips

Purchase the most durable material for your application. It may seem like the cheaper option is the way to go, but you will have more issues with weldability and longevity in the seam welds. The energy-efficiency will drop with a thinner less durable material.

Buy a thicker material to help with less seam issues. An Installer that hot welds will recommend a thicker material so the heated seam welds have more material to penetrate creating less leak and rip problems in the lifetime of your roof. Make sure the top layer of your TPO roof is the thickest. This ensures best energy-efficiency, least amount of possibility of splitting, cracks, and rips.

Always check the ASTM recommendations before purchasing a TPO roof. Your installer can help you select the proper roof to fit your needs best.

References:

http://www.astm.org/SNEWS/AUGUST_2003/obeoli_aug03.html